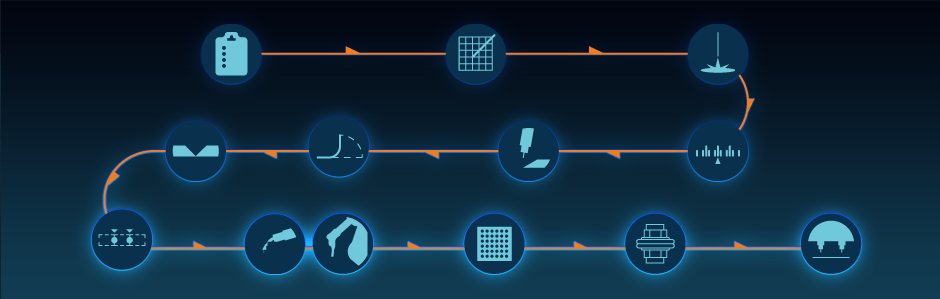

Custom parts

In accordance to customer needs, parts are developed (control plan, amef, ppap), which allows us to create reliable products for our customers.

Cutting iron plates

Iron with thicknesses of up to 120mm. are cut.

Oxy-fuel, plasma or laser cutting

Basic system for cutting carbon steel and low alloy steels. Plasma cutting is used on stainless steel, aluminum and copper. Laser cutting is used on fine metal plating, wood, plastic, fabric or ceramic.

Precision Adjustment

Millimetric adjustment of parts with the use of presses, lathes, and CNC machine centers, robotic welding, rectifiers, and the equipment needed for the most precise tolerances.

Beveling with Oxy-fuel Cutting

Used for producing straight and circular beveling, depending on product needs.

Bending and straightening with presses

We use high precision equipment to for part development, such as industrial specifications for flatness and bending.

Sand and shot blast

This assures clean metal parts for assembly and finishing processes.

Spot welding

Part assembly done with an apparatus to assure that the assembly is correct.

Welding

Welding is the process of joining two materials that are usually metal, generally achieved through a fusion process in which the parts are welding by melting both of them and by adding a melted metal to achieve a spot (welding point) which forms a strong bond when cooled.

Robotic welding

Robotic welding is the use of mechanical programmed tools (robots) to automate welding processes for the operation of welding machines as well as for holding parts. Robotic welding is used for spot welding and arc welding and it is applied to large scale production.

Punching and punch lasers

Punching on CNC punching machines is an automated mechanical operation that uses precise special tools (punches) and (matrices) for cutting. This is achieved by making holes in plates (to separate one metal part from another one to obtain a determined shape).

Mechanical assembly

When it is not feasible to join parts by welding, we use the least possible number of easily placed screws, nuts and bolts.

Machining

Machining is done with the use of a cutting tool, which removes material from the piece worked upon in the form of shavings, which gives it the desired shape.